Manufacturing

Meet all your customization needs, provide OEM and ODM.

Our factory is equipped with advanced technology and automated production lines to ensure efficient production and consistent product quality. Our production facilities cover an area of more than 5,000 square meters and have a team of more than 100 highly skilled professionals who work tirelessly to meet the growing needs of our global customers. With 10 fully operational production lines, we can produce up to 500,000 products per month while maintaining a 99% product qualification rate. Such a strong production capacity enables us to provide a diverse range of products to meet the various needs of the beauty and medical industries.

We use high-quality raw materials, which are imported from South Korea to ensure the safety and performance of each product. Provide reliable solutions for various anti-aging scenarios.

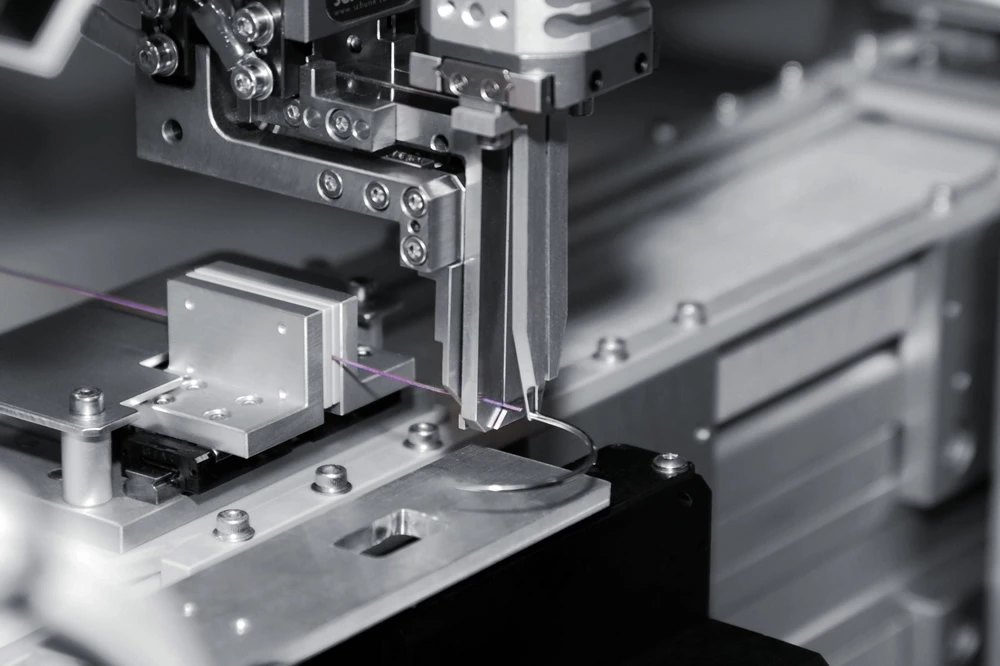

Our factory is equipped with the latest machinery and automated systems, which enable us to maintain high production capacity while ensuring product consistency. This advanced equipment helps us streamline production, reduce errors, and meet the growing demands of the market efficiently.

Our skilled production team is the backbone of our factory. With extensive industry experience, our professionals ensure every product meets the highest standards of quality and precision. They are continuously trained to stay ahead of industry trends and maintain operational excellence.

We employ state-of-the-art production technologies and optimized processes to ensure maximum efficiency and superior product quality. Our innovative manufacturing techniques, combined with continuous process improvements, guarantee the consistency and reliability of each product.

A streamlined manufacturing workflow ensuring precision, quality, and efficiency from raw material selection to final delivery.

01

All raw materials are purchased from SAMYANG(Korea), quality is guaranteed.

02

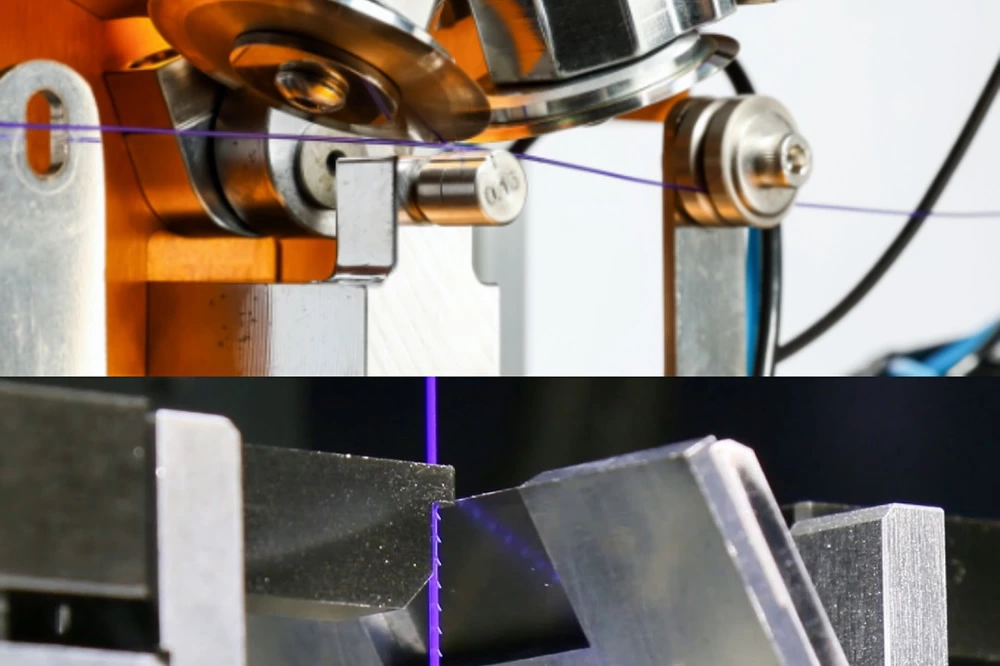

We're equipped with the most advanced thread cutting equipment from Germany for processing.ensuring that the shape,depth and angle of the thread Cog are done accurately.

03

Every batch of thread will be tested by professional equipment, or according to the customer's requirements, the tested value of tensile in scientific lab is up to of 260-600kn(USP1/0-USP3/0)

04

Each thread is strictly selected and assembled by technician in a class-10,000 aseptic workshop, quality and hygiene is assured.

05

All products are sterilized with ethylene oxide for more than 24 hours.

06

Tensile test and humidity test are done once again, to ensure tensile value is good and the humidity value is between 0.04 to 0.08 according to thread model.

07

Packaging and sealing are done in the drying oven to ensure that each product is completely sterile.

08

We will also continuously share the latest product and technical information,and provide technical guidance to our customers, to ensure that the customers can have a pleasant purchasing experience with us.

Feel free to fill out our contact form below and our support team will get back to you within 24 hours.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.more details